3D Printing and Modeling

1 Competition Overview

1.1 Name

【BRICS2025-ST-109】3D Printing and Modeling

1.2 Purpose

Additive manufacturing technology (3D printing) is an advanced manufacturing technology that constructs three-dimensional objects by layer-by-layer material deposition, widely applied in aerospace, medical, automotive, and other fields. Its core advantage lies in enabling high-precision manufacturing of complex structural components. For example, metal powder bed fusion technology can produce lightweight aerospace parts, while bio-based materials and 4D printing drive innovations in medical implants and functional materials. The Additive Manufacturing Skills Competition will focus on advanced technologies, comprehensive capabilities, and innovative thinking to build a closed-loop growth platform integrating “learning, practicing, competing, and applying” for participants.

1.3 Participants

1.3.1 Age Requirement

Participants must be over 16 years old and under 22 years old, with no gender restrictions.

1.3.2 Team Composition

Each team consists of 5 members: 2 competitors, 1 translator, 1 coach, and 1 team leader.

2 Competition Content

2.1 Competition Tasks

The competition includes 3 tasks as follows:

Task 1: Additive Manufacturing Equipment Simulation Operation (1 hour)

Using the provided task document and additive manufacturing equipment simulation platform, complete the assembly of 3D printing equipment, including printer part selection, assembly, and report generation. This task assesses participants’ ability to assemble 3D printing equipment.

Task 2: Virtual Operation Evaluation of Metal 3D Printing (1 hour)

Using the provided task document and additive manufacturing equipment simulation platform, complete the virtual operation evaluation of metal 3D printing, including operating metal printing equipment, model slicing, printing operation, post-processing of metal printed parts, and report generation. This task assesses participants’ proficiency in metal 3D printing processes.

Task 3: Original Work Presentation (15 minutes)

Teams design and manufacture original works integrating digital technologies and applications. Submitted works must be original and not previously awarded in other related competitions. Plagiarized works will receive zero points. Work requirements are detailed in Table 1:

Specific Content | Deliverable Format | Assessment Points |

Product Innovation Description | Proposal Document | 1. Solution framework conditions; 2. Solution objectives; 3. Technical scheme; 4. Functional description; 5. Safety indicators; 6. Operation instructions; 7. Explanation of tools and data used. |

Product PPT Presentation | PowerPoint File | 1. Information collection and planning phase; 2. Decision-making phase for hardware/software selection (digitalization); implementation phase; 3. Project |

Table 1 (continued)

Specific Content | Deliverable Format | Assessment Points |

| | demonstration phase; 4. Timeline (from planning to demonstration). |

Product Video | MP4 Video | 1. Production process; 2. 360-degree display or movement of the product; 3. Additional video introduction required for simulated products. |

Declaration and Authorization | Documents | Attachment: Original Project Declaration. Attachment 2: Project Copyright Authorization Letter. |

2.2 Submission Instructions

(a) The innovation description must be a Word document (≤8 pages). The defense PPT must be a PowerPoint file (≤10 slides);

(b) Product design must include source files named with the “Project Name”;

(c) Video files must be in MP4 format (≤100MB, ≤2 minutes, resolution: 720×576 (4:3) or 1024×576 (16:9));

(d) The original project declaration and copyright authorization letter must be signed by the author.

2.3 Score Weight

The score distribution for each task is shown in Table 2:

- Score Weight Distribution of Competition Tasks

Task | Name | Score Proportion (%) |

Task 1 | Additive Manufacturing Equipment Simulation Operation | 40 |

Task 2 | Virtual Operation Evaluation of Metal 3D Printing | 30 |

Task 3 | Original Work Presentation | 30 |

Total | – | 100 |

2.4 Competition Duration

The duration for each task is shown in Table 3:

- Duration of Competition Tasks

Task | Name | Duration (min) |

Task 1 | Additive Manufacturing Equipment Simulation Operation | 40 |

Task 2 | Virtual Operation Evaluation of Metal 3D Printing | 40 |

Task 3 | Original Work Presentation | 15 |

Total | – | 95 |

3 Evaluation Criteria

3.1 Evaluation Principles

3.1.1 Comprehensive Principle

The expert and referee teams will evaluate results based on the principles of “fairness, impartiality, transparency, scientificity, and innovation”. Participants will be assessed comprehensively on design, equipment operation, and safe production practices.

3.1.2 Module Independence Principle

To ensure fair and objective assessment, each competition module must be evaluated independently. Performance in one module must not affect the conditions, execution, or evaluation of subsequent modules. This principle ensures:

- a) Independent assessment of specific skill areas;

- b) Clear diagnosis of participants’ abilities in each module;

- c) Fair competition regardless of prior task results;

- d) Consistency in evaluation and scoring.

Thus, each module must:

- a) Provide a neutral and organized workspace;

- b) Supply independent tools, materials, and data;

- c) Include separate instructions and objectives;

- d) Allow participants to start without relying on outputs from previous tasks.

Evaluation must assess task-specific abilities within each module based on predefined technical standards.

3.2 Distribution of Evaluation and Measurement Scores

Evaluative (subjective) and measured (objective) scores are allocated to design scoring schemes and competition tasks, as detailed in Table 4:

- Distribution of Evaluation and Measurement Scores

Task | Name | Evaluative Score | Measured Score | Total |

Task 1 | Additive Manufacturing Equipment Simulation Operation | 5 | 35 | 40 |

Task 2 | Virtual Operation Evaluation of Metal 3D Printing | 10 | 20 | 30 |

Task 3 | Original Work Presentation | 15 | 15 | 30 |

Total | – | 30 | 70 | 100 |

3.3 Evaluation Scores

Scoring Method: A panel of 4 referees, including one rotating referee (who scores other teams but not their own). Three referees independently assign weighted scores, and the average weighted score is calculated. Referees’ score differences must not exceed 1 point; otherwise, they must justify their scores, and a consensus score is determined under the chief referee’s supervision. Weighted score criteria are shown in Table 5:

- Weighted Evaluation Score Criteria

Weighted Score | Description |

0 | Below industry standards in all aspects, including “no attempt” or unacceptable performance |

1 | Meets industry standards |

2 | Meets industry standards and exceeds them in some aspects |

3 | Achieves industry-expected excellence |

3.4 Measurement Scores

Scoring Method: Multiple scoring groups (4 referees each) are formed. All referees in a group deliberate and agree on a single score for each participant. Examples of measured scoring are shown in Table 6:

- Examples of Measurement Scoring

Type | Example |

Full or zero points | Integrity of a printed part (1 point): score is either full or zero. |

Deductions from full points | A printed part with 10 critical dimensions (2 points total): 0.2 points deducted per non-compliant dimension (e.g., 4 deductions = 2 – 0.8 = 1.2 points). |

Points added from zero | 5 key dimensions in reverse modeling (5 points total): 1 point awarded per compliant dimension (e.g., 2 compliant dimensions = 2 points). |

3.5 Evaluation Process

3.5.1 Result Scoring

Submitted works are scored according to event evaluation standards.

3.5.2 Penalty Deductions

Participants will face deductions for the following violations:

- a) Accidents due to improper operation: 10–15 points deducted; severe cases result in disqualification;

- b) Equipment damage or environmental pollution due to rule violations: 5–10 points deducted; severe cases result in disqualification;

- c) Disturbing order or interfering with referees: 5–10 points deducted; severe cases result in disqualification;

- d) Non-compliance with regulations (e.g., messy tool placement, disorganized workflow, improper attire, incomplete documentation): 5–10 points deducted based on severity.

3.5.3 Sampling Review

To ensure accuracy, the supervision team rechecks scores with a sampling rate of at least 30%. Discrepancies are reported to the expert team leader in writing for correction and confirmation.

3.6 Score Tabulation

Scoring groups independently score assigned modules. In-process and post-task scores are combined, with daily workpieces scored the same day. USB data is sealed and submitted to the chief referee for safekeeping. All score sheets must be signed by referees and submitted to the expert team leader.

3.7 Ranking

Scores will be aggregated for ranking. In case of tied total scores, Task 1 scores will be used as the tiebreaker, followed by Tasks 2 and 3 in sequence.

3.8 Result Announcement

Results will be announced at the closing ceremony.

3.9 Awards

3.9.1 Certificates

Participating teams will receive award certificates issued by the competition organizers.

3.9.2 Gold, Silver, Bronze Medals, and Merit Awards

The competition will award gold, silver, bronze medals, and merit awards. Teams from all countries will be ranked collectively. The top 6 participants in each event will receive gold, silver, or bronze medals and certificates; participants ranked 7th to 9th will receive merit awards and certificate

3.9.3 Other Awards

Certificates will be issued to expert group members and referees. Organizations making outstanding contributions to the competition will receive the “Outstanding Contribution Award.” National organizing units that actively organize participation, conduct pre-competition training, and have no rule violations will receive the “Excellent Organization Award.”

4 Technical Platform

4.1 Additive Manufacturing Equipment Simulation Platform

4.1.1 Platform Introduction

An integrated platform for virtual simulation learning and assessment in additive manufacturing, developed with real-world processes. It provides FDM equipment debugging assessments and virtual simulation environments for industrial metal and stereolithography equipment.

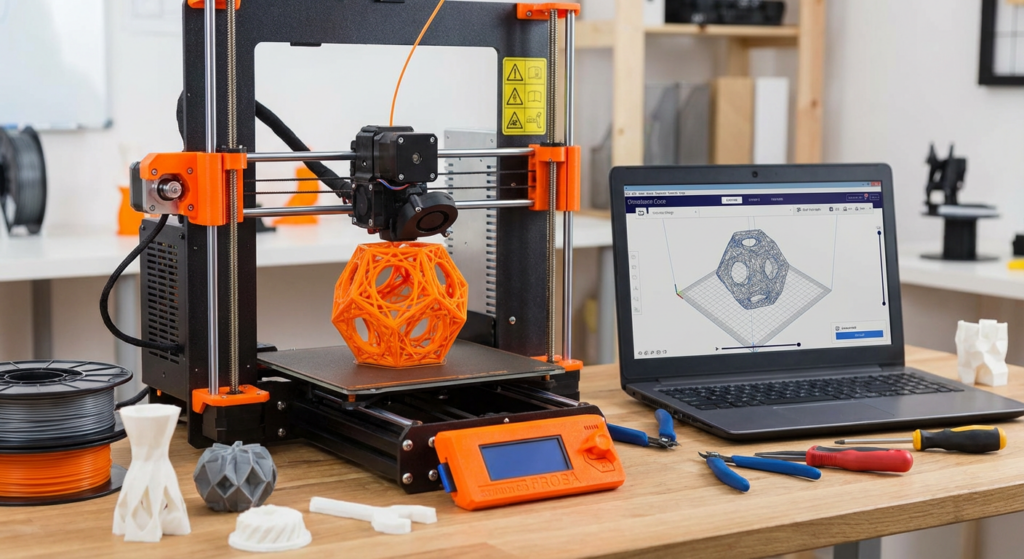

Figure1 Software interface

4.1.2 Platform Functions

The platform supports 3D printing equipment assembly, including part selection and assembly, as well as virtual operation of metal and stereolithography equipment—from slicing and printing to post-processing—with report generation capabilities.

Figure2 Software interface

5 Safety Regulations

5.1 Safety Training

The safety officer organizes training for all referees, staff, and participants, who must pass assessments before competing.

5.2 Safety Facilities

Competition venues must comply with the following:

- a) Layout, equipment, and materials meet safety standards and construction codes.

- b) Necessary safety barriers, emergency exits, fire-fighting equipment, safety operation posters, and evacuation signs are provided.

- c) Entrance security checks prohibit unauthorized items.

5.3 Medical Equipment and Measures

Venues must be staffed with medical personnel and equipped with first-aid facilities and protocols.