Additive Manufacturing: Revolutionizing the Future of Production

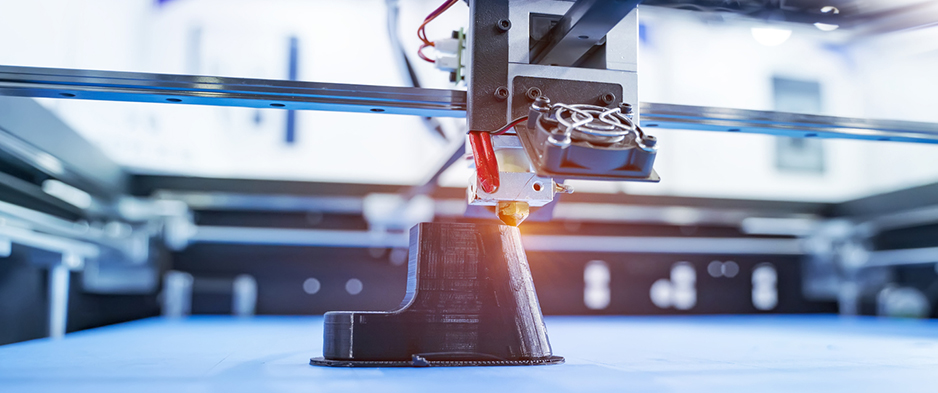

Additive manufacturing, also known as 3D printing, has emerged as a disruptive technology that is revolutionizing the way products are designed, prototyped, and manufactured. Unlike traditional manufacturing processes, which involve subtractive methods such as cutting and drilling, additive manufacturing builds objects layer by layer from digital designs, offering unprecedented flexibility, speed, and cost-effectiveness.

One of the key advantages of additive manufacturing is its ability to create complex geometries and intricate structures that are difficult or impossible to produce using conventional methods. By depositing material layer by layer, additive manufacturing allows designers to unleash their creativity and push the boundaries of what is possible, enabling the production of highly customized and optimized parts for a wide range of applications.

Moreover, additive manufacturing offers significant advantages in terms of speed and efficiency. Traditional manufacturing processes often involve lengthy lead times and high setup costs, especially for small batch production runs. In contrast, additive manufacturing enables on-demand production with minimal setup requirements, allowing businesses to rapidly iterate designs, reduce time to market, and respond quickly to changing customer demands.

Another compelling aspect of additive manufacturing is its potential for sustainability and resource efficiency. Unlike traditional manufacturing processes, which generate significant waste through machining and material removal, additive manufacturing generates minimal waste by using only the material needed to build the final product. This not only reduces environmental impact but also lowers production costs and enhances resource utilization, making additive manufacturing an attractive option for businesses seeking to minimize their carbon footprint and improve sustainability.

However, despite its many benefits, additive manufacturing is not without its challenges. Issues such as material limitations, surface finish quality, and scalability can pose obstacles to widespread adoption, particularly in industries with stringent performance requirements and regulatory standards. Furthermore, the high cost of equipment and materials, as well as the need for specialized expertise, can present barriers to entry for small and medium-sized enterprises.

Despite these challenges, the potential of additive manufacturing to revolutionize the future of production is undeniable. As technology continues to advance and costs continue to decline, additive manufacturing is poised to become increasingly mainstream, transforming industries ranging from aerospace and automotive to healthcare and consumer goods. By unlocking new possibilities for innovation, customization, and sustainability, additive manufacturing promises to reshape the way we design, make, and consume products in the 21st century.